How did this small German foundry develop into a modern precision manufacturing plant?

Release time:

2020-07-15

BAM Machinery, headquartered in the German town of Weiden, is a modern precision manufacturing plant with 170 employees. What is less known is that the factory, which had only eight employees and four machine tools in 2011, was bought by 24-year-old computer student Marco Bauer. In just a few years, Marco Bauer led this small foundry to complete a radical change.

?

?

1. without digitization and automation, no manufacturing plant will survive for long.

In our daily life, orders are placed on the same day and delivered on the next day. This kind of service has been taken for granted by everyone. But in traditional manufacturing, what is the situation on the factory floor? Perhaps people are used to waiting for weeks, especially when personalized small batch production takes longer.

In the face of traditional manufacturing, Marco Bauer regards digitization and automation as one of the great opportunities of our time. He leads BAM in a unique way and is committed to integrating its own precision production and processing expertise with digitization and automation genes.

?

Marco Bauer, Founder of BAM

Marco Bauer is convinced: "Because of the possibilities of new technologies, we need to look at this process chain from a new perspective. In the era of digitalization and industrial 4.0, we can accelerate many processes and make them more flexible. In this field, we want to be the innovators. Without digitalization and automation, no manufacturing plant will survive for long."

?

BAM has 170 employees with an average age of 35. They passionately act as technology pioneers when it comes to combining manufacturing capabilities with digitalization

?

2. unique "make on demand"

What is notable is BAM's online manufacturing service order option. "Including manufacturing, we have digitized the process chain to a large extent," Marco Bauer explained. "This allows us to build on-demand manufacturing platforms and online stores."

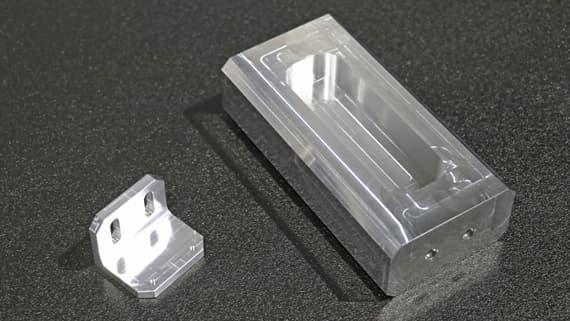

On BAM's website, corporate customers and individuals can order components directly online. After uploading the 3D CAD data defining the required components, the customer receives an order quote within 5 to 10 seconds. Once the order is confirmed, even complex components can be delivered within three days.

?

Components for most orders can be delivered within a few business days

Behind the ability to provide such rapid manufacturing and distribution of industrial components, BAM has achieved a high degree of automation of the entire process chain. "I'm a computer scientist," explains Marco Bauer, "and we employ 30 software developers and developers, and it goes without saying that software enables this kind of automation."

?

Save up to 80% time 3. automated CAM programming

"We worked with our supplier OPEN MIND to streamline the automation process," emphasizes Marco Bauer. "After all, we wanted to get the NC program to the automated production cell as quickly as possible. In the initial project, we succeeded in reducing the time and effort required for CAM programming by 70% to 80%."

BAM has 12 machining centers, 11 of which use 5-axis technology. For a long time, the company has continuously improved the level of 5-axis machining. In 2013, the management decided to introduce hyperMILL from OPEN MIND?CAM solutions.

?

Modern efficient machining relies on 5-axis technology

?

Stefan Bauer, head of production, had successful experience using the software before joining BAM. He said, "hyperMILL.?It is the leading 5-axis machining programming software, with a variety of tilt strategies available at all times, and the ability to select solutions for various geometries and machine motion configurations." In his opinion, because the user interface is clear and intuitive, let a person open the software will clearly realize the hyperMILL?Strong advantages, including excellent machine simulation and collision detection and avoidance functions.

with hyperMILL?Fully integrated hyperCAD?-S, further enhancing the attractiveness of the package solution. OPEN MIND specially developed this set of "CAM-specific CAD" system to help CAM programmers speed up NC coding. It allows users to quickly and easily switch between CAM and CAD, and can also perform a variety of operations, such as adding supports or clamping surfaces, or closing openings.

"By virtue of hyperMILL?With a robust 2.5D, 3D and 5-axis strategy, we have successfully reduced machining center setup and programming time, thereby increasing efficiency and capacity utilization, "says Stefan Bauer, Head of Production. In addition, BAM has significantly increased the complexity of its manufacturing portfolio. This is because, hyperMILL?Efficient machining strategies for almost all application scenarios. Therefore, from the beginning only one set of hyperMILL?The number of software installations has grown to six, and all include 5-axis strategies and hyperMILL.?MAXX Machining Roughing and Finishing Modules of the High Performance Kit.

What Stefan Bauer and his production team appreciate is that OPEN MIND continues to introduce innovative strategies and processes to continuously promote software development and progress. "Using feature technology, related operations and macro databases, hyperMILL?It also lays a solid foundation for automatic programming, which significantly reduces programming time by reusing existing machining knowledge, "adds Stefan Bauer.

?

?

4. individual custom automation

From sales and service to the project team working on custom automation solutions, BAM founder Marco Bauer also praised the good cooperation with OPEN MIND, emphasizing: "Even when dealing with highly complex applications and extraordinary projects, excellent OPEN MIND professionals can always provide us with professional support. A decisive factor for us is the independent development of our own software by OPEN MIND. As a result, we are able to get features tailored for automation projects very quickly, which helps to achieve leapfrog improvements."

Rico Müller, project manager for CAD/CAM automation at OPEN MIND, also affirmed the extensive and close cooperation. He explained about fully automatic programming: "This is particularly effective for components with similar structures and requiring similar processing strategies. Because BAM produces a considerable number of component types, we have built interactive user guides into the automation system. Now, our CAM programmers only need to set a few parameters to expand the range of production components and significantly reduce the total amount of programming work."

?

Related News